PolaPi Zero Review

Maker Pierre Muth’s camera project is a creative mix of nostalgic Polaroid printing and high-tech digital capabilities

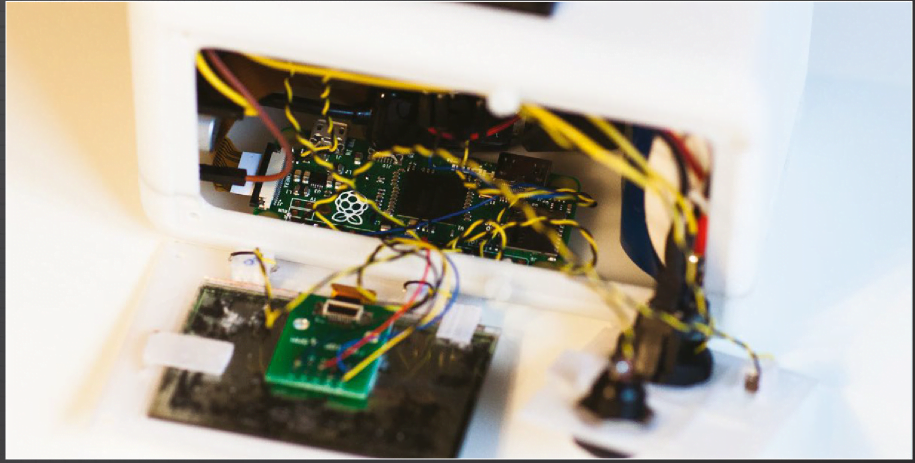

Recipe

- Raspberry Pi Zero

- Thermal receipt printer

- Sharp memory LCD

- Official Pi camera module

- 3D-printed case

How did you come up with the idea behind designing the original PolaPi and the PolaPi Zero?

I was first inspired by a couple of other camera-based development projects, named the PrintSnap and Polatherm Camera. These gave me some ideas for when I developed the original PolaPi model. I like the idea of the Polaroid camera being able to not only show the picture you just took to your friends, but to physically print the picture as well.

After the original version was produced, I sat down with fellow developer Vit Hasek and discussed the possibilities of making the device smaller and more convenient. This is what started

– The nano printer used here prints on regular receipt paper, which means printing quality isn’t the best

- 3A voltage regulator

- 7.2V battery

the development of the PolaPi Zero. He came with a very clever idea that I didn’t have enough time to implement in the first version.

Would you say it’s a blend between classic Polaroid cameras and newer digital cameras?

Yes, I would say so, but there are compromises in both areas. The print quality is obviously bad compared to Polaroid cameras, and the picture files you get are not as great as the ones you can obtain with a recent smartphone. However, in addition to the satisfaction of building something and not only using something, the prints are a lot cheaper and it is fun to use with friends. It opens the door to creative modes and is accessible enough to be rebuilt by a lot of people.

Due to the intricate details of this project, has it been difficult forming a finished product?

I had difficulties on both versions, mainly due to my hardware choices and my lack of knowledge on certain domains. On both versions, the main issue was the internal buffer of the printer. The print speed changes with the darkness of the image. It means if the print is bright, less pixels have to be added and thus the paper advance is quicker, and the

CREATOR pierre muth is a long-time Raspberry Pi tinkerer and engineer, who likes to explore how best to integrate the Pi into everyday items

Printing on-the-go:

One of the biggest issues Pierre faced with this project was the original printing speed. However, thanks to a series of software tweaks he implemented, he could get his taken images fully printed in just a matter of seconds

Adding printing functions to the case: Thanks to the personalised casing, Pierre could simply slide a cheap thermal printer into the top of the unit. It’s attached with just four miniscule screws, which have their own cut-out groove in the unit

Tinkering the camera settings: To best maximise the capabilities of the Pi camera module used here, Pierre used its onboard Python library. Within here, he could tinker with the finer points of the camera set up, and toggle how it would work in tandem with the printer 3D-printed case: Pierre took the time to design the entire casing of the PolaPi Zero in Autodesk. He stripped back the complexity traditionally found in 3D printing, choosing to print just three plastic components for the PolaPi Zero other way around. The screen I’ve chosen also gave me some head-scratching. I was close to choosing a more standard way, such as the PiTFT of the first version. These Sharp ‘memory LCDs’ are nice to look at, though, so I decided to continue. They are perfectly visible in sunlight as they are reflective LCD and are – as the printer – pure monochrome.

At first, I started by generating the image data to be sent on the SPI port in the program, but I faced some problems when sending the 12 Kbytes of the image in one block. Fortunately, I found the wrobell library for this LCD: https:// github.com/wrobell/smemlcd. I spent a bit of time figuring out how to compile the library with Autotools and deal with the error messages it returns.

The case itself looks fantastic.

Did you use anything in particular to design and print it?

I started from scratch with the Autodesk 123D design free software. If you’re a bit familiar with CAD software, it seems quite limited at first. On the other hand, it is possible to achieve a lot of things within an hour, including the learning time.

I tried to limit the number of printed pieces. For tactile buttons, it is a small strip and a square part to hold the button in place. The front and back plates are fixed with four screws, and the hole threads are just made with a tap in the case plastic. The case can then be easily opened.

What sort of printer did you use for the project? Was it easy to implement into the small frame of the PolaPi Zero?

I think I used one of the cheapest thermal printers out there – you can easily get it from Adafruit. It is the Cashinotech CSN-A3. It is meant to be slot-in, so just four small screws will hold it well in the case. It uses a special kind of paper, the very cheap receipt thermal paper, and you can find much of it from recycling outlets. There is a big debate about the waste of this

“IT’S CHEAP AND FUN FOR FRIENDS”

paper type, as the receipts are usually just thrown away. Nevertheless, here the aim is different. You will never print as many tickets as a supermarket, and in most cases the prints are meant to be kept.

How effective is the Raspberry Pi in this project? Did you find it easy to work with?

Starting with the Raspberry Pi leads you into a vast world of knowledge to acquire, especially if you’re not confident with Linux. I started playing with them from their first version and I still play with RPIs because of the enormous community. All the installation process of Raspbian became very easy and the libraries development have aided me in my progress. If you still encounter a problem, there is a large probability that someone else has both faced it and provided a solution.

The Raspberry Pi Zero is a bit more ‘closed’ than B models, as there is only one USB port. I liked the facility that copies the Wi-Fi network setup file (wpa_supplicant.conf) from the FAT32 partition to the right place at boot time. I then could work on it by connecting a USB Wi-Fi dongle; so, no screen, keyboard or mouse.

After spending some time with it, how do the end photos look? Are you happy with the results?

Do not expect good prints, of course. It is low-resolution (384×640 pixels) and only black or white in its current form. The grey gradients are the result of the error-dithering algorithm, so don’t look at them too closely. However, they’re unique prints, and a lot of fun to produce. In the future, I’ll be looking to improve the quality of them further.

– The LCD screen at the rear of the unit is used to manage prints, as well as see on-the-spot previews of taken images