YAMAHA GT-5000 Review – In A Spin

A high-end turntable from Yamaha puts Noel Keywood in a spin. Read about their new GT-5000 Review.

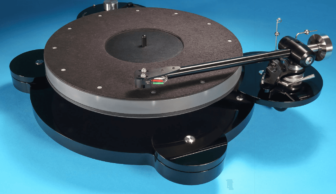

A slightly unusual high- end turntable is how I’d describe the Yamaha GT- 5000 – and expensive too at £. But Yamaha build a quality product and this barely-liftable turntable is no exception. It’s a high- end design finished in deep gloss black lacquer, as our pictures show. And it had me a bit baffled.

Bafflement came when we opened the large box to find no acrylic dust cover. Have they left it out? No, a cover is available at – er – £ extra. Absence of a dust cover for a turntable as standard is a puzzling omission.

The GT-5000 is a heavyweight able to match my Garrard 401 on Martin Bastin plinth – meaning barely liftable. Enormous mass stabilises a turntable, making it immune to vibration and acoustic feedback and here Yamaha go all out to match old classics. It weighs a massive 26.5kgs with 5kg platter installed, so needs a firm platform. I use a specially built low table for my Garrard to avoid rocking motion, and it sits on a ‘quiet’ floor. The GT-5000 would need a similarly firm surface.

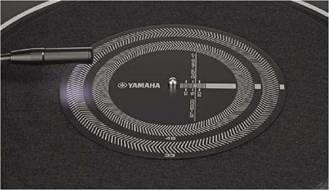

There are two speeds, 33rpm and 45rpm, with no option for 78rpm. Drive to the platter is via belt from an a.c. synchronous motor, fed from in internal crystal-locked sine wave power supply for both speed stability and adjustability. Speed can be varied in 0.1% steps over a +/-1.5% range, by turning a knurled wheel that sits beside the platter in a pillar. Unfortunately, the pillar carries no stroboscope light to set speed, nor a cue light as in Technics Direct Drives. To set speed Yamaha supply a strobe disc and strobe light that plugs into a rear power socket – for set up procedure, not everyday use. This leaves the GT-5000 looking visually dull: there are no lights to liven things up, as with Garrard or Technics classics, or many others. A lovely feature of high-end turntables always was – and still is – their meaningful light displays, something the GT-5000 sadly lacks.

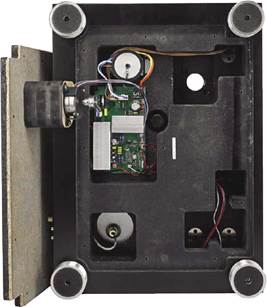

The power supply is internal, a mains lead plugging into rear – no wall-warts or external supply boxes here. It makes for a neat set up. With dimensions of 546mm wide, 411mm deep and 221mm high the GT-5000 is big as you’d expect. Since a standard 19in rack is 483mm wide it should fit; it just squeezed onto ours. Contributing to weight is a substantial two-part platter comprising heavy brass hub and solid aluminium outer rim. Unfortunately, its mass makes start up very slow; at times I wondered whether it would start, the initial delay was so long. But small green (33/45) LEDs on the speed button flash until correct speed has been achieved, turning steady green typically after 12 seconds.

The arm uses wrapped carbon fibre construction for rigidity and light weight, having a tapered crosssection – a precedent set by Rega long ago. The headshell is removable, using a standard bayonet fitting. What comes as a surprise with this arm is that it is straight, increasing lateral tracking error but making bias correction unnecessary; there is no anti-skating mechanism as a result. More on this complex subject in the Arm Geometry box out.

Two balance weights are supplied, covering a very wide cartridge weight range of 2gm – 9.5gm and 9gm – 20gm. The arm can be adjusted for height by raising or lowering the arm pillar, with a hex. key grub screw acting as a clamp. It would appear that the arm plate can be removed to fit an alternative arm but there may well be difficulties in wiring one in and I’m uncertain about geometry; a replacement would need a short effective length of 223mm. But somehow I don’t see many people spending so much on the GT-5000, only to replace its arm.

Another difficulty came with the pin connectors in the headshell leads. Our review sample had seen previous use, the pin connectors were enlarged it seemed and slipped straight off the pins of our cartridges. There were also graunch marks on the sleeves, caused by pliers. So I tried to close the pins slightly using jewellers pliers and a bench clamp/magnifier. This did not work. Using fingers rather than pliers I felt the pin connectors only clicked into place when pushed home hard, so they’re ‘difficult’ connectors. Our office SME309 and my home SME312S have

flared connectors and Litz cables of appropriate quality, that are easier to use. You can of course buy and fit replacement cables – and they come in many varieties: copper, silver, stranded, Litz. As an example see Audio Technica’s picture here of their AT6108 ‘leadwires’ price £, using 29 strand 6N OFC wire – and note the quality connecting pins. Then look at the GT-5000 pins to see why I was disappointed. The instruction manual should explain these connectors and their attachment methodology, but there is no mention.

A pleasant surprise came in seeing balanced XLR outputs, in addition to the usual RCA phono sockets. Cartridges are inherently balanced sources (if not ground referenced) and should ideally see a balanced-input phono stage (where they can be ground referenced). This minimises induced hum and noise – a major problem when looking for high-end performance. Trouble is, there are very few phono amps around with balanced inputs, even though they are nowadays easy to implement using dedicated audio mic preamp silicon chips (THAT Corporation etc). The handbook shows a generic matching amplifier with balanced phono inputs, but there are none.

Or are there? The Yamaha A-S3200 I reviewed in our November 2020 issue did not have them but there is a matching C5000 preamp that is fully balanced throughout, including balanced Phono stage input.

Definitely worth looking at for glorious pictures of its extreme high-end construction (copper screened transformers etc). Or there is Aqvox of Germany with their Phono 2 Ci MkII. A further opening of wallet is needed to exploit this feature.

Note that the GT-5000 has no internal preamplification: these are passive outputs. A fully balanced internal preamp delivering balanced Line output would have been a real plus-point I feel, achievable at this price level and an elegant way to maximise sound quality from the whole.

SOUND QUALITY

I fitted the Yamaha GT-5000 with Ortofon A95 and Audio Technica OC9X SH (Shibata) moving coil (MC) cartridges. The phono preamplifier was an Icon Audio PS3 Mk2 (valve) with input transformers. Amplifiers were an Audiolab 6000A Play and an Icon Audio Stereo30 SE (valve, single-ended). The amps fed (alternatively) Martin Logan ESL-X hybrid electrostatic loudspeakers through Chord Company Signature Reference screened cables.

Both cartridges have boron cantilevers and a cool, analytical sound. I was surprised to hear the opposite to what I am used to from using them in many turntables. With Dire Straits Brothers in Arms (Mobile Fidelity, 12in, 45rpm), Money for Nothing came over as full bodied, dark to the point of sounding warm, yet dynamically powerful: the drum rolls thundered out and the bass line was massive. This rather surprised me but it was a consistent trait after many LPs had rolled by; I suspect the arm material, not being a metal, has a lot to do with it.

With Two Countries, One Heart (HiFi Direct, Italy) Fanfare For The Common Man similarly sounded dynamically bold, opening kettle drum strikes had power and there was wonderful timbral resolution – I got to hear the character of the drum better than usual. My end-of- side test on this LP where Rosella Caporale sings Time To Say Goodbye, the GT-5000 moved up to full points, sounding absolutely glorious. She came over in more believable human form than I have heard before – bit of a shock. There was not only resolution of every vocal nuance but great insight into vocal texture as well: I was left thinking perhaps we should not be listening to metal tonearms.

And the other issue that surprised me was both Ortofon A95 and Audio Technica OC9X MCs sounded less dry and remorseless (boron cantilevers) than I am used to. I was again puzzled. The Audiolab 6000A Play best suited this presentation, bringing in more speed than the Icon Audio Stereo30 SE, whose smoothing qualities were not needed here.

I had a feeling the GT-5000 might get an interesting result from our Audio Technica VM750SH moving magnet cartridge, with its tapered aluminium cantilever and Shibata stylus. And this was so. Connected to the Audiolab’s MM phono stage bass was a tad shy; connected to our Icon Audio PS3 Mk2 valve phono stage feeding the Audiolab’s Aux 1 line input I hit a sweet spot. Now there was even more body and strength to vocals (boron be gone) and tight powerful bass: Hugh Masekela’s trumpet blared out on Uptownship, from his LP Hope, hand drums at the intro were vivid and the slow kick drum strikes had heft. At this point the GT-5000 was showing it had clean dark sound, massive bass power and superb resolution of instrumental and vocal timbre.

What was wrong? There was some mellifluous-ness. Stereo images were soft around the edges, not chiselled in stone as in Rega’s Planar 10, and bass was on the warm and fulsome side; kick drums had power but a soft edge; I suspect the arm’s resonance is responsible for this (see Measured Performance). All the same, I ended up loving the sheer richness of revelation here and the sense of power in the sound. Deeply exciting and very convincing: this turntable would make anyone love LP.

CONCLUSION

Yamaha seemed to have pushed the boat out here, fitting a very unusual arm to a high-spec belt drive turntable in massive plinth. In engineering terms the arm is left-field, but for peculiar reason – non- metallic construction I suspect – it works very well in subjective terms, delivering a sound that is full bodied and organically exciting – meaning convincingly realistic. Fabulous sound quality then, if not perfect. The turntable and plinth add in powerful bass and great dynamics.

With poor instructions, many practical problems and no dust cover except as an extra, the GT-5000 is not a fully worked out product at practical level:Yamaha can and need to do better. All the same I loved its sound.

EXCELLENT – extremely capable.

VERDICT

Yamaha Music Europe

GmbH (UK)

+44 (0)1908 366700

www.uk.yamaha.com

MEASURED PERFORMANCE

The 3150Hz test tone of a DIN 45-452 test disc was reproduced as exactly 3150Hz on our Wow&Flutter meter (after adjustment), with no wander around nominal. The GT-5000 was eerily stable for belt drive, looking more like a Direct Drive.

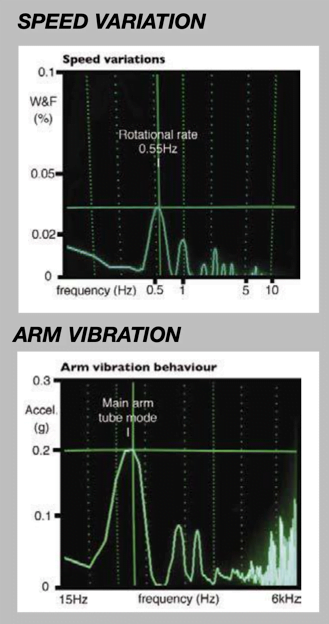

Low speed wander results in low Wow (low rate speed variation), the GT-5000 hovering around 0.08% and Flutter 0.04% – good results. Total Wow&Flutter (DIN weighted) measured 0.05%, a very good result. Measured to the Japanese JIS Standard total Wow&Flutter (wtd) was 0.03%, JIS always giving a lower reading than German/European DIN. Our analysis shows the usual peak at 33rpm (0.55Hz), at low-ish level, plus harmonics and minimal flutter (right).

The arm, in spite of what appears to be wrapped carbon fibre construction and a tapered shape, had a strong first bending mode at 150Hz, our analysis of vibration, using a Bruel&Kjaer accelerometer on the head shell, shows.

This is a classic tube resonance – not expected from modern arms. The head shell is reasonably free of severe high frequency resonances.

The turntable measured well but the arm was poor by modern standards, due to a strong main bending mode resonance. NK

Speed error 0%

Wow 0.08%

Flutter 0.04%

Wow & Flutter (DIN wtd.) 0.05%

YAMAHA ARM GEOMETRY

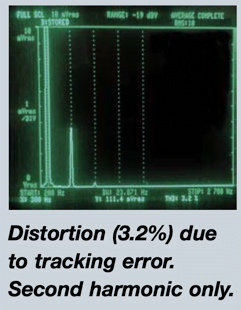

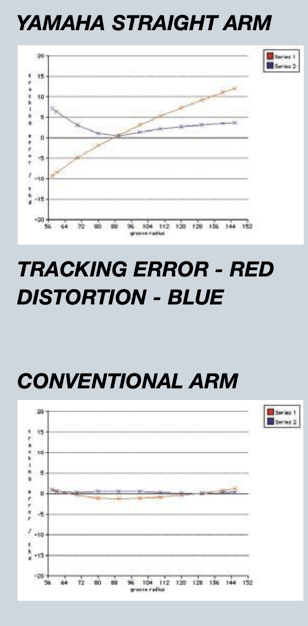

A straight arm with no angular offset of the cartridge – I was intrigued. Plugging the data into my spreadsheet that uses Stevenson’s equations gave a graph you can see here (right). Distortion due to lateral tracking error (blue) reaches 4% – and more on inner grooves. Results are not comparable to a conventional arm that manages less than 1%, as our analysis shows (lower right). So, approximately x4 more distortion than a geometrically optimised arm.

If this was the case then the typical 0.8% distortion figure I measure when testing cartridges in our SME309 arm would be 3.2% in the Yamaha arm – and it was exactly that under measurement – see the analysis. Angling the cartridge in the head shell by approximately 10 degrees reduced distortion from 3.2% to 0.5%, showing what is possible from optimised geometry. This measurement also confirmed both cartridge (AT OC9X SH) and test disc (CBS STR-112) are capable of such low distortion, test discs in particular being a limiting factor when measuring distortion.

As a rough guide then, Yamaha’s straight arm produces x4 more distortion than a conventional arm. Sounds horrible and certainly isn’t wanted, but we’re talking innocuous sounding second harmonic here (see the analysis) – so no subjective disaster. At about 5%-10% second harmonic becomes just audible as a lightening of tone, rather than the graunching noise associated with modulated higher harmonics.

Quite why Yamaha have decided to use non-optimal geometry in a top tonearm is difficult to fathom however. Was it to eliminate the cost of a bias correction system, or to give a shorter, stiffer arm? Yamaha’s arm is short at 223mm effective length and the cartridge has what is known as underhang (-17mm) where the stylus traces a path that crosses behind the turntable spindle – most arms have +17mm overhang. So totally different geometry. Whilst a shorter arm should be stiffer, Yamaha’s was not stiff at all measurement with an accelerometer showed. The structure could certainly be improved.

Yamaha’s literature stays resolutely silent about reasons they decided to go straight, where everyone else is bent – if you’ll pardon the pun. It is all a tad baffling.

I found this arm gave good sound quality but it needs technical development to lessen structural resonant modes and improve image definition. An angled headshell would reduce tracking error at no extra cost too. NK

Yamaha GT-5000 Turntable Unboxed | The Listening Post | TLPCHC TLPWLG

Yamaha #GT5000 #Turntable Referencing the esteemed turntables of the golden age of Hi-Fi, the GT-5000 expands on this heritage in the pursuit of pure ...

The whole idea behind their straight arm is to accept a higher tracking error but, by doing so, to also eliminate the need and problems associated with anti skating. They claim the gain in musicality of allowing a better free flow outweighs the increase in tracking error. In a conventional tonearm (or if angling the headshell in a straight tonearm as you did in your review) anti skating becomes necessary as the cartridge is no longer aligned with the pivot (unlike with a straight arm) thus creating skating force, thus requiring anti skating. And the problem id that anti skating is a static force trying to correct a variable force. If you ask me, I think Yamaha’s approach makes sense and perhaps they’re right and everyone else is wrong.

I am very late to this comments section but a new interest in this TT has sent me to various reviews. Alex, in his comments above echos what other reviewers have pointed out regarding Yamaha’s decision re the arm geometry. Here in Australia at least Yamaha has been open about why they chose this geometry in spite of its increase in distortion levels. As Alex has stated anti skating in no longer needed.

In your review you state that the arm is not made of metal. This in not accurate. Courtesy of Ed Kramer’s review in SoundStage Ultra in Australia – “The main shaft, or wand as it’s sometimes referred to, is constructed from a 9-layer composite of materials. The inner core is an aluminium tube “plated” with a layer of copper on both the inside and outside walls. The aluminium/copper tube is then laminated with multiple layers of ‘3k’ carbon fibre alternating with glass fibre.”

So whatever good things you heard via this arm it is not because it is “non-metal”.

Also, one error in your musings over your listening session I must point out. The late Hugh Masekela on Hope does not play a trumpet. It is a flugelhorn which sounds very different to a trumpet.

I made my own error in my previous response so apologies for that. It is soundstageaustralia that Ed Kramer writes for

Hallo

Ein maximaler Spurfehlwinkel von +-10° laut Datenblatt geht gar nicht. Absoluter Schwachsinn. Und soetwas nennt sich High-End.